Investment Casting

Precision Investment Casting

- Investment Casting, also known as Lost Wax Casting, is a precision casting process that provides design flexibility and significant cost advantages

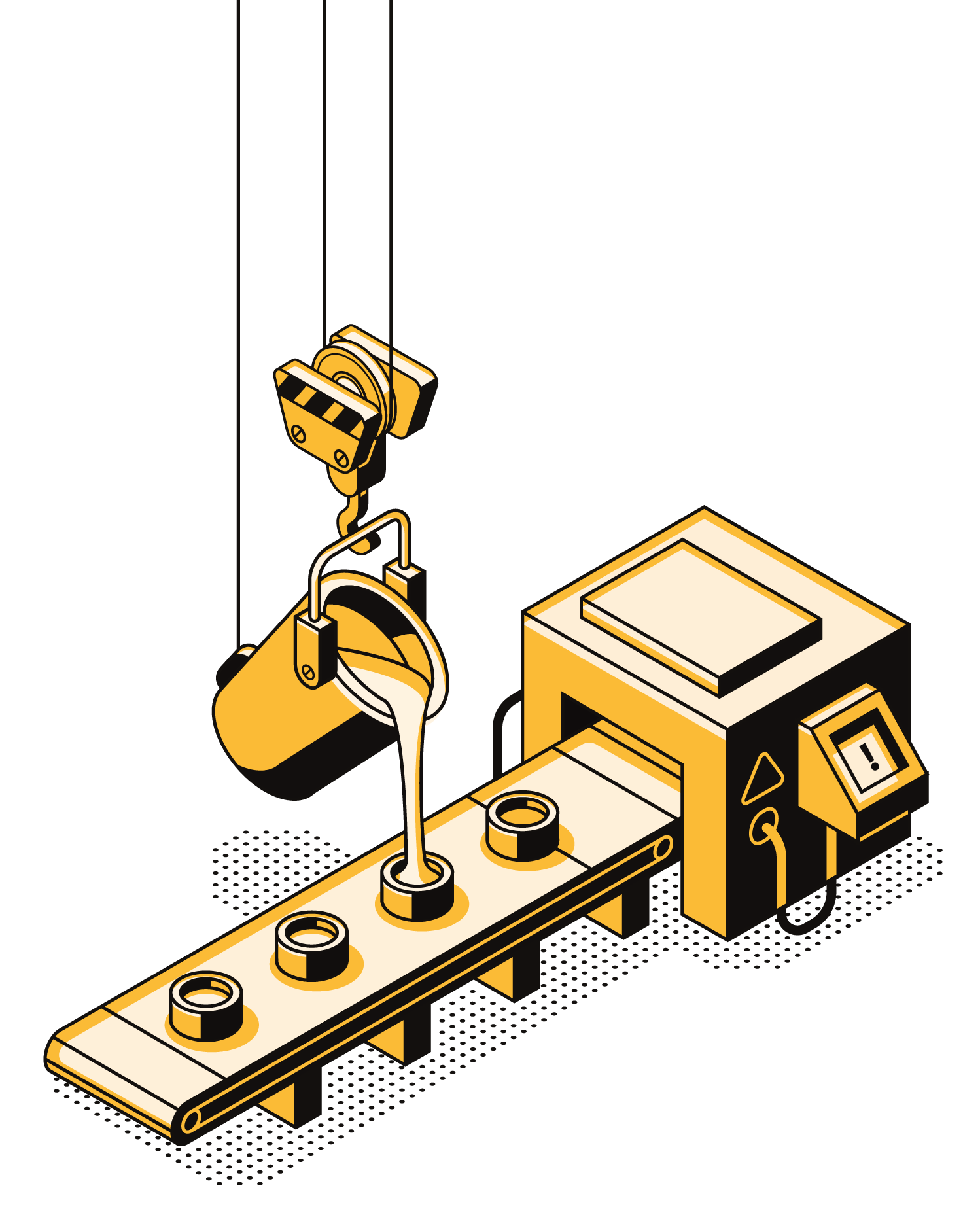

- Investment Molding Process

- The Investment Casting process involves pouring molten metal into a mold that has been created using a wax model. Once the mold is made, the wax model is melted and drained away. Hollow cores can be affected by using a heat-proof core that prevents the molten metal from totally filling the mold.

- Investment Casting is generally used for small castings, though it can be used to produce much larger components.

- Dimensional tolerances of ± 0.003 in./in. are readily achieved with the investment casting method.

- Delicate parts with walls as thin as 0.025 in. can be created by utilizing investment casting.

- Investment Casting Benefits

- Mass production with precision.

- For products your customers can count on, you need parts that are cast to last. Euro Metrics offers superior investment casting in a wide range of alloys for even the most intricate designs and complex geometries.

- IMPECCABLE INVESTMENT CASTINGS

- Exacting details and fine finishes

- Got a difficult, tricky, tiny, or heavy parts design? Challenge accepted. Euro Metrics global network of ISO certified suppliers ensure casting integrity and reliability, minimizing deviations and defects while maximizing manufacturing efficiencies .

- DIMENSIONAL ACCURACY AND QUALITY

- Consistently close tolerances

- Delicate parts, thin-walled housings, undercut forms, and tight-tolerance tubings. We investment cast whatever OEMs need – even when nobody else can. Supported by a global team of highly trained engineers, Euro Metrics delivers mass produced yet highly accurate investment cast parts and components.

- FAST PRODUCTION WITHOUT RUSH FEES

- Achieve better speed-to-market times

- Euro Metrics ability to speed production – and your ability to deliver to your customers faster – is unparalleled. As supply chain experts with a worldwide reach, we’re the best at combining swift delivery times with lower-cost investment casting solutions.

- Get Started

- Want to find out if steel, stainless steel, aluminum, nickel, ductile iron, or grey iron investment castings are right for your application?

- There are several advantages of using investment casting to get the part you designed. One such advantage is the ability to make more intricate forms—even forms with undercuts. Also, the investment casting process leaves a very smooth surface, which is created without a parting line—something that would be unavoidable in other processes.

- The accuracy of investment casting is second to none. Even parts with the higher precision can be casted with little to no machining or detailing required. And since the finished piece will need no welding or assembling, you save on time and cost that would be required using other methods.

- With new alloys developed that allow for more complex parts to be cast, the process of combining several parts together to get the intricate shape can be eliminated. This not only saves time and money, but it also diminishes the chances that an error could occur while combining the parts.

- One of the biggest advantages of investment casting is that it is possible to produce a very wide variety of products across different industries. This versatility is a definite plus over other casting methods that either have difficulty producing some designs or cannot produce them at all. Also, many different metals and alloys can be used in investment casting, diminishing the need for designers to worry about the production of the casting they have visualized.

- Investment Casting Materials

- Carbon Steel

- Stainless Steel

- Aluminum

- Nickel

- Ductile Iron

- Grey Iron

Our services are dedicated for large-series production inquiries.

Contact us!

Leave your contact details, we’ll get back to you within 2 working days. Fill in all the details, thanks to which we will be well prepared for the interview and we will use this time effectively!